Fermentation is a key process in many industries, including food and beverages, pharmaceuticals, biofuels, and biotechnology. Whether developing new products, scaling up production, or optimizing existing processes, fermenters play a crucial role in ensuring the success of these ventures. As technologies progress, the gap between pilot scale and industrial scale fermenters has become a focal point for many manufacturers. This article delves into the differences between pilot and industrial scale fermenters and the importance of bridging this gap for the efficient scaling of fermentation processes.

Understanding the Basics: What Are Pilot Scale and Industrial Scale Fermenters?

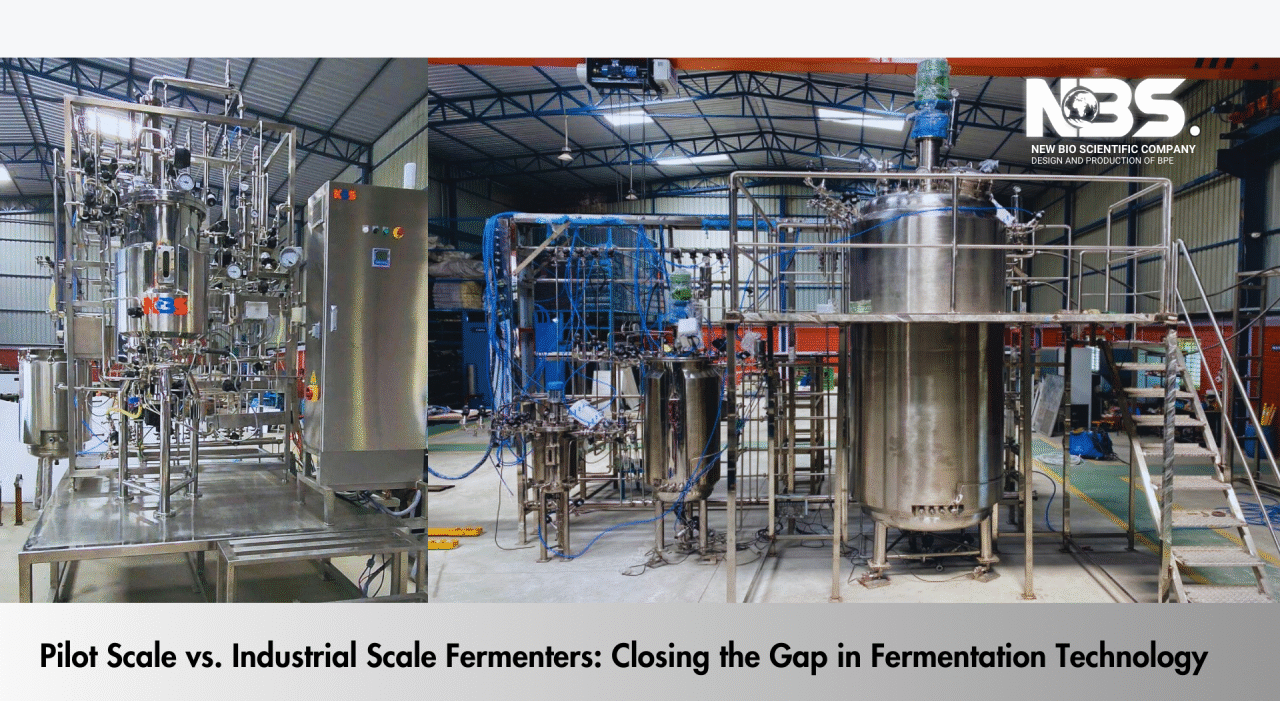

Pilot Scale Fermenters: Pilot scale fermenters are smaller, experimental versions of industrial fermenters. They are designed to simulate the conditions of full-scale production but are used primarily for testing, research, and optimization. Typically ranging from 10 to 500 liters in volume, pilot fermenters allow researchers to evaluate the feasibility of a fermentation process and make adjustments before moving to larger-scale production.

These systems are equipped with features that replicate industrial fermenter conditions—such as temperature, pH control, oxygen transfer, and agitation—while offering the flexibility to test different variables like nutrients, feed rates, and inoculum types. Pilot scale fermenters are a bridge between the laboratory bench-top fermentations and full-scale industrial production, making them an essential tool in the development and scaling-up of fermentation processes.

Industrial Scale Fermenters: Industrial scale fermenters, on the other hand, are designed for large-scale production. They typically range from thousands to tens of thousands of liters in volume and are used in commercial production settings where the final product will be manufactured and distributed. These fermenters are often highly automated and integrated with various control systems for efficient monitoring and optimization of fermentation parameters.

At this scale, factors such as heat transfer, mass transfer, and mixing efficiency become significantly more complex, and the stakes are higher because the cost of failure is much greater. Industrial fermenters must operate continuously with minimal downtime, and the control systems must be finely tuned to ensure the desired product yield and quality.

Key Differences Between Pilot and Industrial Scale Fermenters

Scale and Volume: The most obvious difference between pilot and industrial scale fermenters is the volume. Pilot fermenters allow for smaller, more controlled experiments, typically operating in the range of 10 to 500 liters. In contrast, industrial fermenters can hold thousands of liters of fermentation broth, with larger systems being employed for mass production.

Complexity: As the scale of fermentation increases, so does the complexity of the system. Pilot scale fermenters are relatively simpler in design and allow for more flexibility in terms of experimentation. Industrial fermenters, however, require advanced automation systems, including sensors, pumps, and controllers to manage the larger volumes and ensure consistency in product quality.

Cost and Investment: Pilot scale fermenters require lower initial investments and operational costs compared to industrial fermenters. This makes them a cost-effective option for research and development, especially when trying to fine-tune production processes before scaling up. Industrial fermenters, on the other hand, involve significant capital investment and higher operational expenses, making it crucial to ensure that the transition from pilot scale to industrial scale is successful.

Process Control: In pilot scale fermenters, the ease of manual intervention allows operators to closely monitor and adjust parameters during the fermentation process. In contrast, industrial fermenters rely on sophisticated process control systems to handle variables like temperature, pH, dissolved oxygen, and nutrient concentration. These systems ensure that the process runs smoothly at a much larger scale, where small deviations can lead to significant changes in the final product.

Throughput and Yield: The main goal of industrial fermenters is to maximize throughput and yield, often with a focus on minimizing costs while maintaining product quality. While pilot scale fermenters aim to test and refine processes, industrial scale fermenters are optimized for efficiency and consistency. Achieving the desired yield in an industrial system requires close attention to scaling factors and potential changes in the microbial culture’s behavior as the system size increases.

The Challenges of Bridging the Gap

Scaling a fermentation process from pilot scale to industrial scale presents several challenges:

Scalability Issues: The behavior of microbial cultures in small-scale fermenters doesn’t always replicate in large-scale systems. For example, mixing, heat transfer, and oxygen supply can behave very differently in a larger vessel. What works well in a 50-liter fermenter may not be as effective in a 5000-liter industrial fermenter, leading to inconsistent yields and poor-quality products.

Oxygen Transfer and Mass Transfer: At larger scales, the ability to maintain effective oxygen transfer and mass transfer becomes increasingly difficult. In pilot scale fermenters, agitation and aeration can be precisely controlled, but scaling up these parameters in larger systems can lead to inefficiencies, reduced oxygen levels, and poor mixing, which can hinder microbial growth and metabolism.

Time and Risk: Scaling up fermentation processes is time-consuming, and the risk of failure increases as the scale increases. Transitioning from pilot scale to industrial scale requires rigorous testing, process optimization, and careful monitoring to avoid costly mistakes.

Process Variability: Industrial scale fermentation often involves many variables, including temperature, pressure, and nutrient composition. Pilot scale fermenters allow researchers to test a range of variables, but there are always unique challenges at the industrial scale, especially when it comes to maintaining consistent conditions throughout large fermenters.

Strategies for Closing the Gap

Computational Modeling: Advanced computational models can be used to predict the behavior of fermentation processes at larger scales. These models simulate various parameters and can provide insights into how to optimize the process during scale-up, including the effects of mixing, heat transfer, and nutrient utilization.

Scale-Up Studies: A systematic scale-up approach that involves performing small-scale experiments and progressively increasing the scale is essential for bridging the gap. Understanding the key scaling factors—such as the ratio of vessel height to diameter, mixing time, and oxygen transfer rates—can help optimize the transition from pilot to industrial scale.

Process Analytical Technology (PAT): The implementation of PAT tools in both pilot and industrial scale fermenters can help monitor real-time data, allowing operators to fine-tune fermentation parameters. PAT ensures that the fermentation process remains under control as it is scaled up, improving the likelihood of a successful transition.

Modular Systems: Many companies are turning to modular fermenters that can be scaled up in stages. This flexibility allows manufacturers to adjust the process incrementally, ensuring that any changes in scale are manageable and that the process is optimized at each step.

Conclusion

The gap between pilot scale and industrial scale fermenters is a critical challenge in fermentation technology. As industries push for greater efficiency and product consistency, the ability to scale up fermentation processes without compromising quality becomes paramount. By leveraging advanced modeling, scale-up studies, and innovative process technologies, manufacturers can bridge the gap and achieve successful, large-scale production. With these strategies in place, the potential for more efficient and sustainable fermentation processes is boundless, driving growth in industries that rely on fermentation as a key production method.